Feel free to follow me on the social media below and add your email to the box for notifications of new posts on here.

The Rail Yard

Florange Blast Furnaces: Rail yard looking to the balst furnaces.

Florange Blast Furnaces: Signal/control room for the rail yard.

Florange Blast Furnaces: The site actually had its own station.

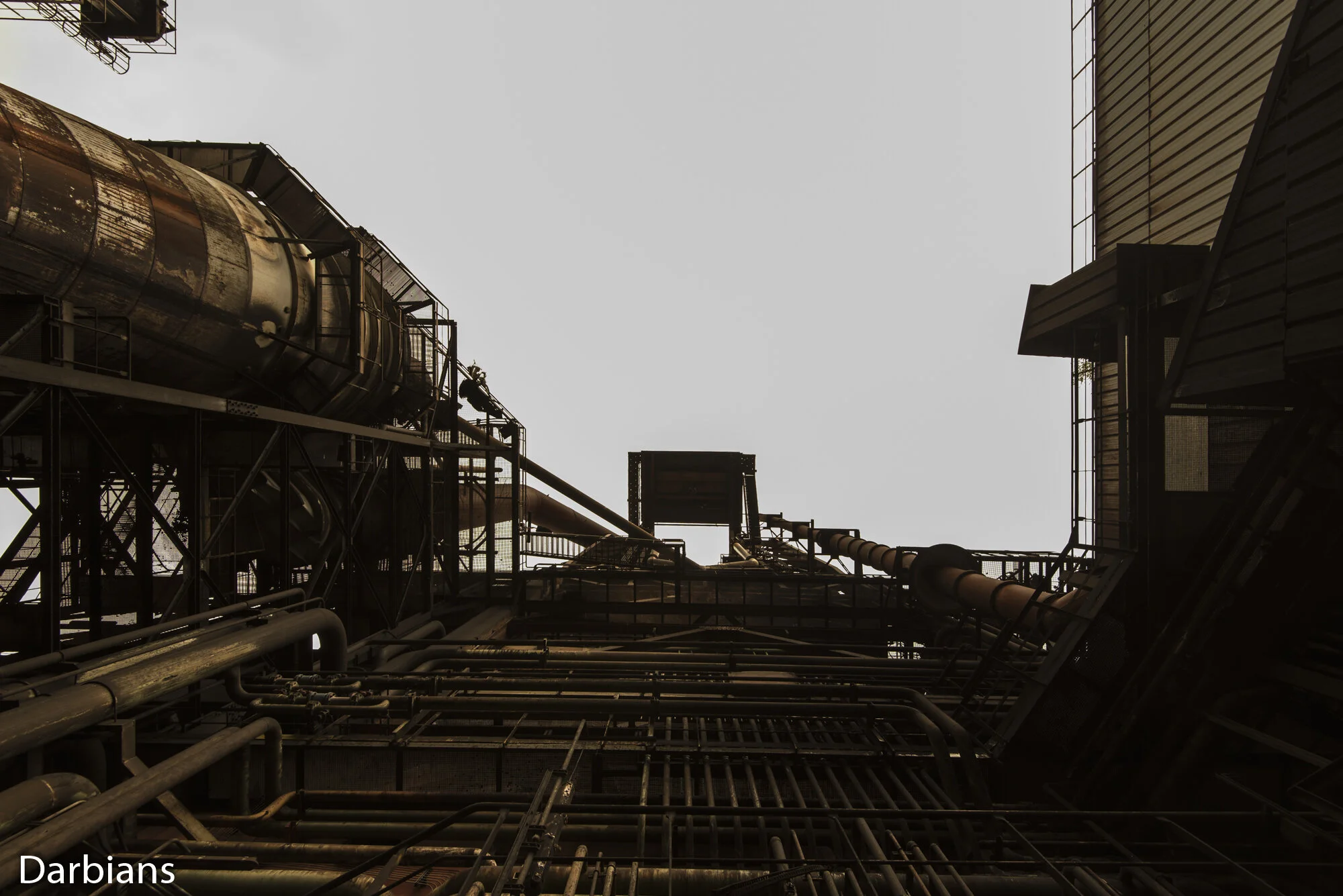

Florange Blast Furnaces: Looking up at one of the blast furnaces. The large cylinders are stoves to create the hot air.

Florange Blast Furnaces: The wagons would deposit the ore into the hoppers below.

Florange Blast Furnaces: The charging conveyor took the iron ore up to the furnace.

Florange Blast Furnaces: A large distribution system. This could be the sinter plant but I am unsure.

Blast Furnaces

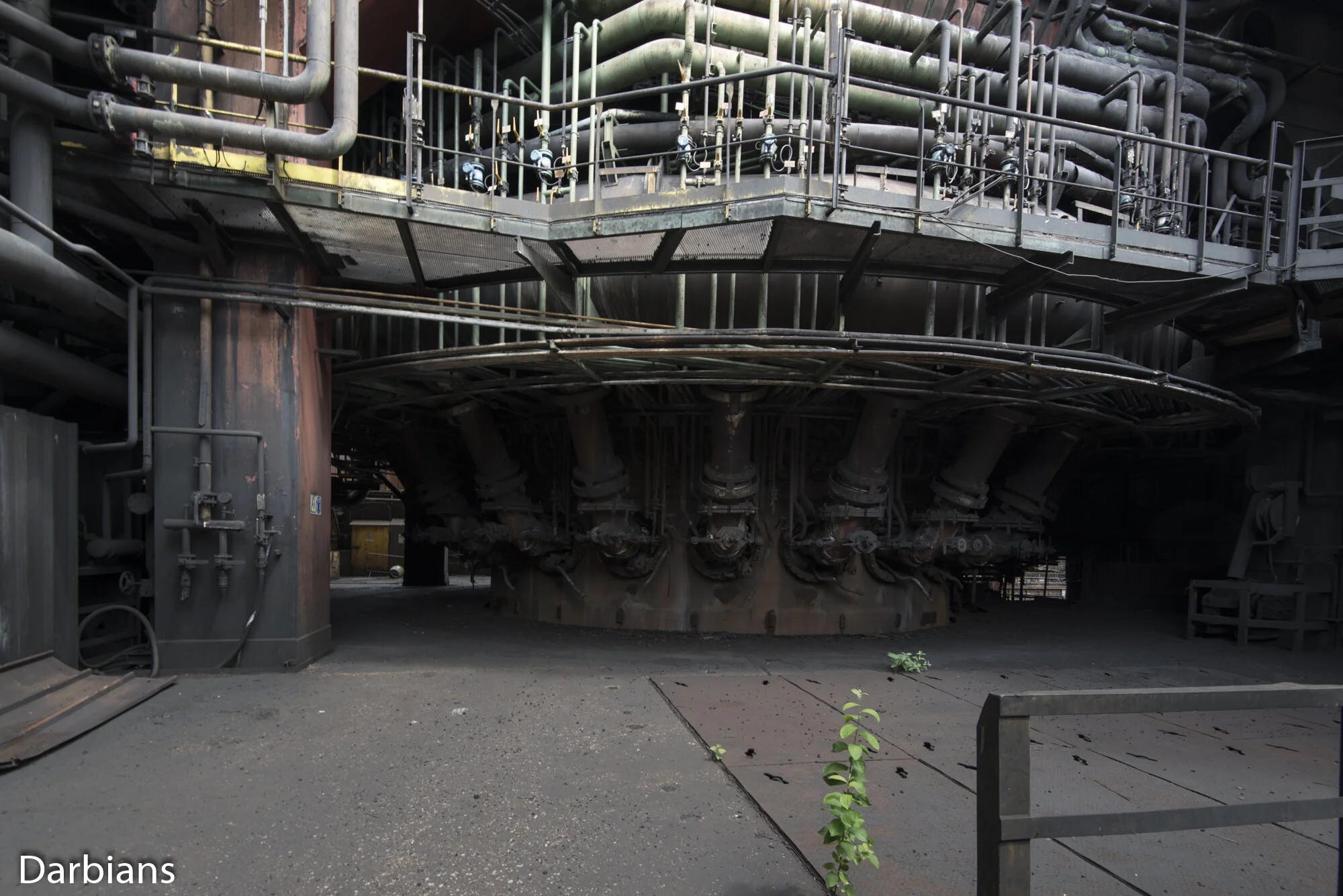

Florange Blast Furnaces: Hot air is blasted through the pipes known as tuyeres at over 1000ºc

Florange Blast Furnaces: Looking up at one of the blast furnaces.

Florange Blast Furnaces: Looking up under the charging conveyor.

Florange Blast Furnaces: A small control control room.

Florange Blast Furnaces: Outside the small control room you get a cleaner view.

Florange Blast Furnaces: Another view looking up at the furnace.

Florange Blast Furnaces: The piipes from the top take the waste gas to the cleaning chamber and on to the stoves to reheat the air. the rest of the gas traveled six km to Richemont power station.

Florange Blast Furnaces: Looking back from near the steelshop.

Feel free to leave your views on this article below.